Infineum scientists create powerful new tool which could fulfil unmet customer needs

Infineum scientists have created a powerful new tool, believed to be unique worldwide, which could fulfil unmet customer needs and improve sustainability credentials, through collaboration with leading universities, research labs, and industry experts.

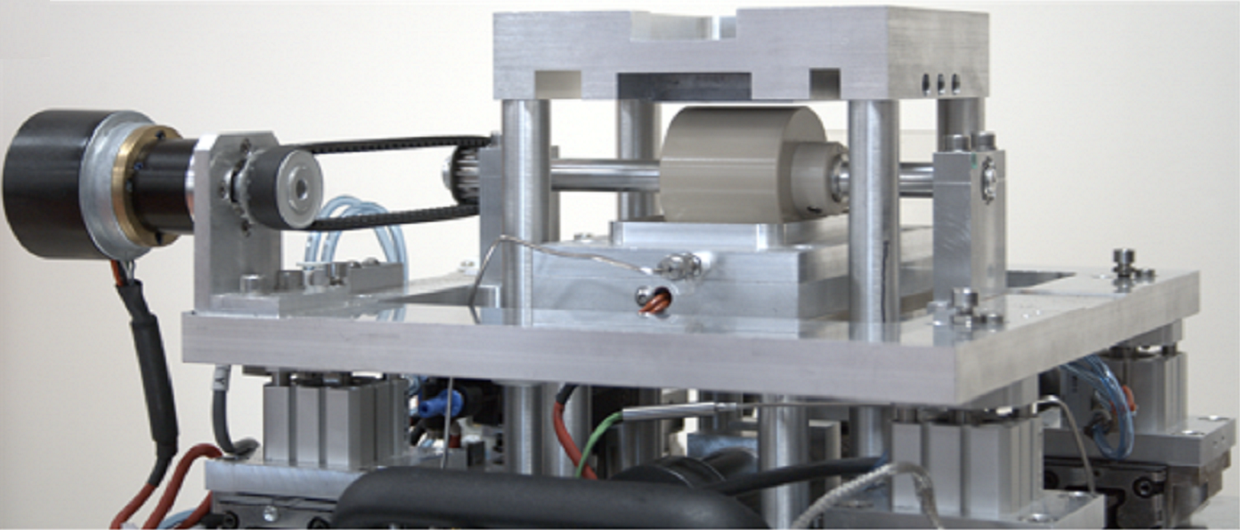

The tool, a beamline tribometer (pictured above), enables the design of new products from a molecular level and gives results in real time. It has already attracted interest from OEMs and lubricant marketers.

A team of Infineum employees came together to find answers to improving fuel economy, the biggest driver in the fuels and lubricants industry today.

Collaborating with academia to lead our innovations forms part of ‘Partnerships for Goals.’ This is one of our four priority United Nations Sustainable Development Goals which inform our sustainability strategy.

Since 2015, they have been collaborating on this extremely complex project with leading universities and research labs, including experts from Cambridge University, ISIS Neutron and Muon source and Diamond Light Source (where the tribometer is based). It’s involved bringing together diverse skillsets spanning physics, engineering, tribology and physical chemistry, to study and use some of the most powerful x-ray and neutron beamlines in the world.

It is commonly accepted that organic friction modifiers work by forming a layer between the metallic engine components and the engine oil. However, there is no unified theory which relates the structure of the layer to the resultant friction.

“We questioned our industry model”, said Infineum Principal Scientist Professor Pete Dowding. “Not only did we want to determine how molecules behave, but we wanted to discover how they can be used for the molecular level design of additives.”

Less viscous oils reduce friction; however, this can lead to engine wear. Therefore, developing new additives which maximise friction reduction, will improve engine performance and fuel economy while reducing environmental emissions.

By mimicking the engine metal-on-metal contacts, the tribometer determines how chemical structures form and enables improved additive design. Pete explains:

“Unlike most other tribometers, ours performs the experiment in a real-world environment while also giving results in real time. This avoids slow result analysis after and outside of the experiment.”

Building an accurate tribometer to work on both X-ray beamlines at Diamond and neutron beamlines at ISIS was a real technical challenge, according to Pete:

“When we started, no such equipment existed. Combining knowledge and capabilities was key to overcoming complex barriers.”

The tribometer has been through several evolutions and the group has had to master extremely complex techniques. The first prototype that was delivered only partially worked, but drastic modifications and re-building a second version solved the problem.

As they could only access the beamline facilities at Diamond and ISIS a couple of times each year, perseverance was key through the design, test and improve phases.

Once the tribometer was operational, the next barrier was interpreting the results. Cambridge student Sandy Armstrong, alongside experts from ISIS and Diamond, wrote bespoke models to analyse the data. Pete concludes:

“Next steps are for the team to build on what’s been achieved with one additive, so we can understand how formulations work.”

A summary of the project and a link to the technical paper can also be found on the ISIS Neutron and Muon Source’s Science Highlights pages.